Preparing batteries for use with Deuteron Technologies Loggers

All Deuteron loggers are designed to operate from single-cell protected lithium-polymer batteries. A large variety of shapes, sizes and capacities of suitable batteries are made, almost always in China. Following changes in shipping restrictions of lithium batteries in 2017, it is often not permitted or possible to ship batteries from Deuteron together with the loggers. Where possible, Deuteron will send some batteries to users separately. Whenever Deuteron supplies such batteries, this is done as a service on a non-profit basis. Since Deuteron does not manufacture such batteries, it cannot provide a guarantee for them. Such batteries have limited lifetimes and slowly lose capacity as they age. Users often wish to find the most suitable size and shape of battery for a given experiment. For these reasons, users of Deuteron Loggers are encouraged to prepare their own batteries. In general this involves selecting and buying a suitable size of battery, and then attaching a connector to it.

Selecting a suitable size and shape usually involves the user finding a battery that has sufficient capacity to run a given measurement session, but is small and light enough for the animal and experiment in question.

Firstly one must estimate the required capacity of the battery. This is done by multiplying the current consumption of the logger by the duration of the measurement session. Typical current consumption figures of some loggers are given below. For a more accurate estimate, contact Deuteron for updated current consumption figures. The actual current depends on the version of the software running, and the use of additional devices in the logger such as the motion sensor and high-intensity LEDs for tracking. It also depends on the memory card used.

Typical current consumption figures for a logger during a recording session with a 3.75V battery are as follows:

| Logger type | Current consumption, mA |

| Spikelog-16 | 47mA |

| MouseLog-16B | 35mA |

| RatLog64 (32 channels) | 62mA |

| RatLog64 (64 channels) | 85mA |

| Audiolog-2 | 25mA |

For example, if an experiment requires 100 minutes of recording on a MouseLog16B, proceed as follows:

Estimate the time that a battery must last in practice. This might include some time that the logger is turned on before the measurement starts. The power consumption in “monitor mode” is higher that that in recording mode. So for a 100-minute experiment, you might want to ensure that the battery is good for 2 hours. This the total capacity needed is 2h x 35mA = 70mAh. However, since the battery loses capacity as it ages, you may want to specify a battery whose initial capacity is about 20% higher than this, say 85mAh. Furthermore, battery suppliers often test and specify their batteries under conditions more favorable than those encountered when powering a logger. This may be because they specify the capacity until the voltage has dropped to 3V, whereas the logger will stop recording once the voltage drops below 3.4V. It could also be because the batteries are tested at a low current, such as 5mA, whereas the logger takes 35mA. Lastly, it could be because the suppliers somewhat exaggerate the capacity of their batteries. As a result, the correct battery to specify should be around 100mAh, rather than 85mAh.

Some batteries are supplied without a built-in protection circuit. Always use batteries that include a protection circuit.

Estimating and size and mass of a battery

As a rule of thumb, the volume in cubic centimeters (cm3) of a lithium-polymer battery will be roughly 0.25 + 0.01 C, where C is the capacity of the battery in mAh. For example, the volume of a 150mAh battery will be about 1.75cm3. The mass in grams will be very roughly 2 times the volume in cm3, so the mass of a 150mAh battery is about 3.5g. A selection of available sizes of cells, including the protection circuit, is given in the table below.

| Capacity (mAh) | Length (mm) | Width (mm) | Height (mm) |

| 45 | 15 | 10 | 3 |

| 80 | 21 | 12 | 5 |

| 90 | 25 | 12 | 4 |

| 120 | 30 | 10 | 4 |

| 150 | 30 | 20 | 3 |

| 160 | 35 | 12 | 4 |

| 170 | 25 | 20 | 5 |

| 170 | 30 | 12 | 5 |

| 180 | 35 | 12 | 4 |

| 180 | 30 | 17 | 5 |

| 180 | 35 | 12 | 5 |

| 180 | 30 | 14 | 5.4 |

| 185 | 40 | 20 | 3 |

| 220 | 40 | 12 | 5 |

| 220 | 40 | 12 | 5 |

| 240 | 25 | 20 | 6 |

| 250 | 35 | 20 | 4 |

| 250 | 33 | 13 | 5.8 |

| 250 | 20 | 20 | 6 |

| 250 | 22 | 17 | 7 |

| 260 | 30 | 17 | 6 |

| 260 | 40 | 12 | 6 |

| 300 | 30 | 20 | 4 |

| 300 | 35 | 12 | 6.1 |

| 320 | 35 | 15 | 6 |

| 330 | 35 | 20 | 5 |

| 340 | 30 | 20 | 5 |

| 350 | 40 | 20 | 4 |

| 350 | 35 | 20 | 7 |

| 380 | 50 | 20 | 4 |

| 400 | 40 | 30 | 3 |

| 500 | 40 | 30 | 4 |

Buying batteries.

Several hundred different sizes and shapes of lithium polymer batteries are offered by sellers on Ebay (www.ebay.com; search for lithium polymer battery). Such suppliers do manage to ship to most countries, but do so by slow shipping methods, so it typically takes 3 weeks to receive such batteries. An excellent supplier of batteries in the USA is Powerstream (https://www.powerstream.com/li-pol.htm. When looking for batteries, they are often listed by their size code, which is made from their dimensions in order of height, width and length, for example “051230” is the size code for a battery of height 5mm, width 12mm and length 30mm. This might also be listed as “501230”

Attaching a connector

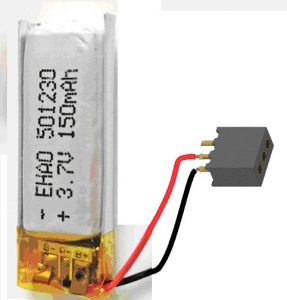

Most Deuteron loggers and batteries use Mill-Max pins and sockets. These are used because they are reliable, compact, and often used elsewhere in electrophysiology laboratories. Attaching them does not require any special crimping tools; they are simply soldered to the wires and covered with insulating material. Batteries are connected to sockets, while loggers and chargers use strips of pins.

On a battery, the central socket is connected to the positive (red) battery wire, and one of the sockets at the side is connected to the negative (black) wire. On loggers and chargers, both side pins are connected to the negative (ground) of the device. This allows the pins and sockets to operate when mated either way round.

The socket strip used for the battery is Mill-max part number 851-47-003-10-001000 obtainable from Digi-Key, Mouser and others. Where the 3-pin socket is unavailable, a longer strip such as the 50-socket strip, (part # 851-47-050-10-001000) can be cut. When cutting a longer strip, cut the plastic above the fourth socket and forfeit that socket; it is not easily possible to cut the plastic between the sockets.

Strip about 2mm of the insulation of the battery wire and solder it to the solder pin of the socket strip as shown below.

Try not to expose more than a minimum length of the insulated wire. After soldering, cover and reinforce the area of the of the soldered pins and a little of the PVC wire with insulating material, such as epoxy glue, insulating epoxy putty, or similar. Sometimes dental cement is available and that can also be used. At Deuteron, black Milliput (https://www.milliput.com/black.html) is used for this. It can easily be purchased in small quantities on ebay. (https://www.ebay.com/itm/Milliput-Black-113g-stick )

Generally, new batteries are supplied in a partially charged state. It may require about two discharge-charge cycles before full capacity cycles are achieved.